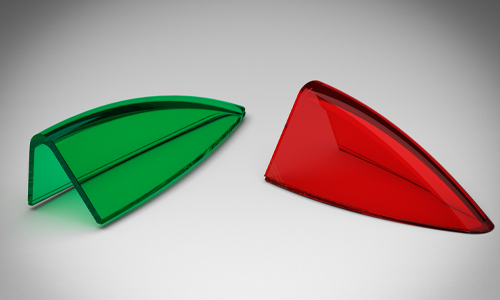

In this two-part study, Taber abrasion and high-velocity particulate impact testing are used to evaluate the suitability of borosilicate glass, polycarbonate, and aviation grade acrylic in exterior jet aircraft lighting applications.

In this two-part study, Taber abrasion and high-velocity particulate impact testing are used to evaluate the suitability of borosilicate glass, polycarbonate, and aviation grade acrylic in exterior jet aircraft lighting applications.

In the aerospace industry, Light Emitting Diode (LED) technology promises to keep planes operating longer with reduced maintenance costs and lower power consumption. With the need to frequently replace burned-out bulbs eliminated, the importance of constructing reliable exterior lighting systems that can maintain safe levels of light output while withstanding exposure to particulate abrasion, thermal, and chemical stresses is necessary for operators to realize the benefits of LED technology fully.

To inform and aid lighting engineers, operators, aircraft manufacturers, and regulators in their evaluation process, Kopp has published a new white paper that investigates the abrasion resistance of transparent materials used in exterior jet aircraft lighting applications. In the first part, the Taber Abrasion test method was used to evaluate how these materials withstand abrasion introduced through routine handling and cleaning of lenses. In the second part, third-party high-velocity particulate impact test was completed at the US Air Force Particle Erosion Test Facility at the University of Dayton Research Institute (UDRI). The particle erosion test apparatus, or “dust-rig,” that was used was designed to simulate erosion effects on aircraft surfaces subjected in flight to dust-laden environments. The results demonstrated severe light loss, and rapid degradation was possible with the hard-coated polycarbonate as compared to heat-strengthened borosilicate glass.

“When our customer's design external aircraft lighting fixtures, they consider the optical, chemical, thermal, and mechanical performance of the cover lens material. Our results indicate that glass lenses exposed to abrasive particulate in the atmosphere will maintain optical output at least two times longer than a plastic lens exposed to the same conditions.”

Adam Willsey, Manager of Research and Engineering at Kopp Glass

As airframes are pressed into nearly continuous service across varying environments, using materials that can withstand particulate abrasion, thermal, and chemical stresses will reduce the total cost of ownership of an exterior light fixture. The results from this two-party study conclude that borosilicate glass lenses can withstand the harsh operating environment of aerospace for more significant periods of time than their plastic counterparts, helping to increase the longevity and reliability of LED exterior lighting systems. Abrasion resistant lenses mean reduced maintenance and operating costs over the life of the aircraft.