To help accelerate UV LED adoption within the UV curing market, we developed a new optical solution that utilizes LEDs of various UV wavelengths to produce a mixed, uniform light output.

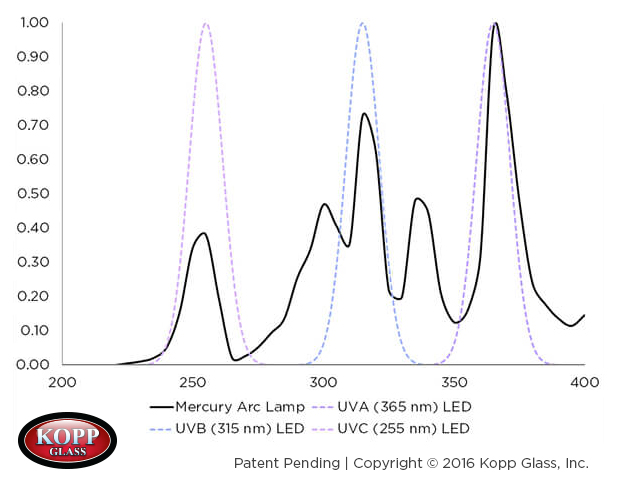

For decades, mercury (Hg) vapor lamps have been the most common light source used for UV curing applications. However, as UV LED technology improves, they’re increasingly replacing Hg lamps, and creating new opportunities for the UV curing market, as well as new challenges. Hg lamps produce a broad spectrum with multiple peaks, while UV LEDs produce a narrow spectrum with a single peak.

The difference in spectral distributions and therefore, irradiance and energy output between the two light sources is a critical hurdle to the full adoption of LEDs into the UV curing market.

Our new optic is designed to create UV LED curing systems that produce a spectrum that mimics Hg lamps, or any other spectrum that is desired. We’re excited to share this new research and optical solution at the upcoming RadTech UV+EB Conference on May 15 through 18, in Chicago Illinois.

New Research on UVA, B, and C Glass Optics Designed to Mix UV LED Wavelengths, Increase Irradiance, and Improve Uniformity

A look at RadTech’s technical conference program shows that UV LED technology will be a main topic of discussion at the conference and that the UV curing industry is focused on rapidly adopting this technology. More than 30 presentations focus on UV LED technology and its application in UV curing.

We’re pleased to participate in the conference session; on Tuesday, May 17 at 4:00 PM we’ll share new research on UV glass optics that can improve the performance of UV LED lighting systems. In his presentation, “UVA, B, and C Glass Optics Designed to Mix Wavelengths, Increase Irradiance, and Improve Uniformity: Design, Simulation, and Analysis,” Brian Jasenak will discuss the current challenges that LEDs present to UV curing, and share research that demonstrates how UV glass optics can be designed to overcome these challenges.

His presentation will review our research and the development of two UV glass optics designed to enhance the performance of UV LED lighting systems by mixing and focusing multiple wavelengths within one LED array.

UV Glass Optic Designed to Uniformly Mix Wavelengths Produced by a Multi-UV LED Array

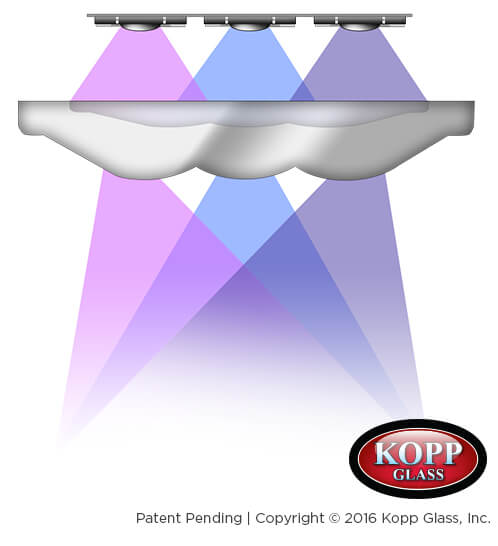

A glass optic capable of transmitting UVA, B, and C wavelengths was developed to focus the energy from different wavelength UV LEDs and produce a singular irradiance pattern that has a uniform wavelength intensity.

The design includes three optical elements that are aligned with three rows of UV LEDs. Based on the UV LEDs used, this irradiance target pattern can be designed to replicate the spectral distribution of Hg lamps. Not only can this optical system be used to create UV LED curing systems that mimic Hg spectral distributions, the UV LED array and optic can be tailored to produce custom spectrums as required by specific applications.

Brian’s presentation will discuss the optical design, the relationship to the UV LED array design, and the results achievable with this type of optic.

UV Glass Optics Designed to Enhance Irradiance and Uniformity

The second half of the presentation will discuss the development of secondary glass optics designed to optimize the performance of UV LED lighting systems. He’ll share results that demonstrate how a secondary UV glass optic can be designed to improve uniformity and irradiance of multi-UV LED arrays. When compared to a flat window cover, a 20% increase in relative irradiance was achieved, as well as a reduction in non-uniformity by 30%. These optical features can also be used to optimize the performance of the UV LED mixing optic.

Optimized UV LED Lighting Systems through Collaborative Innovation

The ultimate performance of an LED fixture is determined by different components of the lighting system, including the optical design, LED selection, array design, material selection, electrical driver and components, and the thermal management system. An iterative, collaborative approach to innovation early in the design process will yield fully optimized UV LED curing systems.

We’ll discuss the collaborative innovation process and how it can be used to create optimized UV lighting systems during our product demo “UVA, B, and C Glass Optics Designed to Increase Irradiance and Improve Uniformity” on Tuesday, May 17, at 10:30 AM.

UV LED Optical System Design Lab

If you can’t make it to our product demo or technical presentation, visit us at booth #714 for a hands-on discussion and review of our optical design capabilities. At our exhibit, we’ll feature our interactive design lab. “The UV LED Optical System Design Lab” which will demonstrate how we collaborate with you during each stage of the new product development process and the benefits that can result. It is critical to collaborate during the early design phases of the lighting system. If the optical components are considered after the LED array design and fixture are finalized, there are limitations to the benefits that an optic can provide, which can ultimately affect the overall performance of the lighting system.

We’re eager to collaborate and help you design custom optics that optimize your UV LED lighting systems. If you have questions about UV glass optics or would like to learn more about the benefits that they provide to a UV LED lighting system, schedule a meeting at the UV LED Optical System Design Lab. Our experts will be available for one-on-one discussions; together we can review your latest UV LED lighting project.

Early collaboration will help you achieve the best results, and we believe our optics can help you develop systems with increased irradiance, better uniformity and cure quality, and flexible working distances. We look forward to meeting with you at RadTech!