In technical glass production, molten glass is pressed and it rapidly cools as it is removed from the mold. This rapid cooling creates internal stresses within the glass piece. When the glass finally cools to room temperature, stresses in the glass can potentially cause spontaneous breakage. Glass annealing is a controlled process of slowly cooling glass to relieve these internal stresses.

In technical glass production, molten glass is pressed and it rapidly cools as it is removed from the mold. This rapid cooling creates internal stresses within the glass piece. When the glass finally cools to room temperature, stresses in the glass can potentially cause spontaneous breakage. Glass annealing is a controlled process of slowly cooling glass to relieve these internal stresses.

The Annealing Process

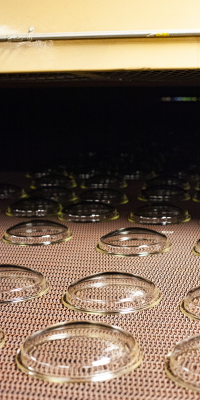

In glass manufacturing, a special type of furnace, called a lehr, is used for the annealing process. A lehr is a long oven that is comprised of different heating zones. Glassware moves through the oven’s zones on a conveyor belt. To ensure maximum stress removal, each product design requires a unique annealing schedule that takes into consideration the glass composition, coefficient of thermal expansion, and thickness.

To begin the annealing process, the glass is cooled to a temperature which allows the atoms to move freely while still preserving the glassware’s dimensional characteristics. The glassware is kept at a steady temperature for an extended period of time to create structural consistency and to minimize stresses. The temperature is unique to each glass composition and the time is determined by the physical design and shape of each product.

Glass cooling occurs between the annealing temperature and the strain temperature. This period is the most important part of the cooling process – it must allow the outside and inside of the glassware to cool at the same rate. At the annealing temperature, which must be above the glass transition temperature, the atoms in the glass reorient. As the glass cools through the transition temperature to the strain temperature, the atoms become rigid in the glass structure.

When cooling occurs slowly, the atoms are able to relax and the result is an unstressed, well-annealed glass product. Controlled glass annealing:

- Ensures material consistency

- Minimizes stresses

- Prevents spontaneous breakage

To learn more about glass basics, download our eBook: