Colored Glass

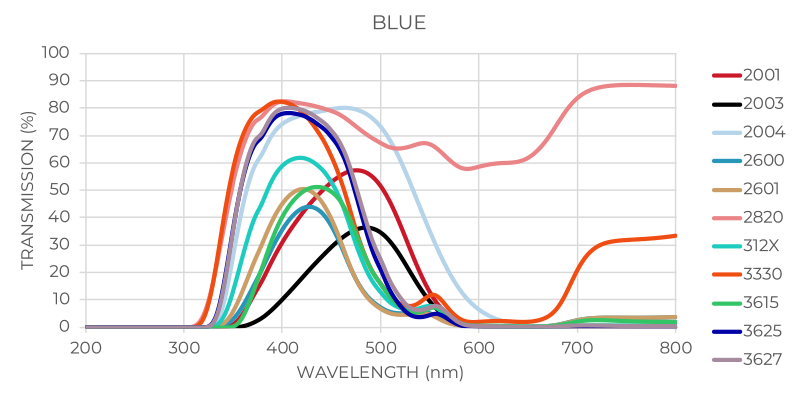

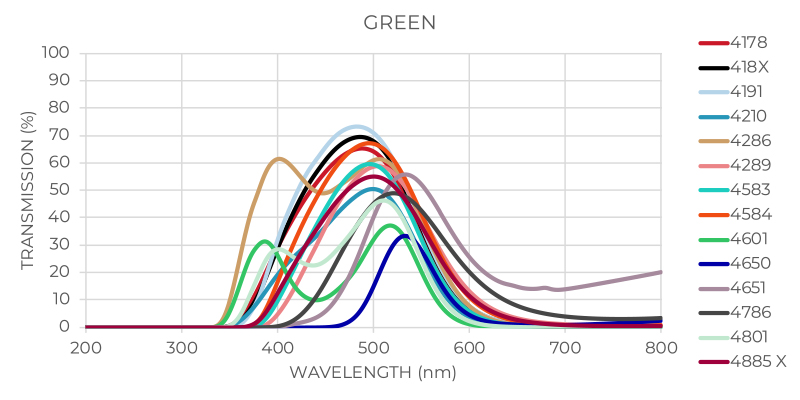

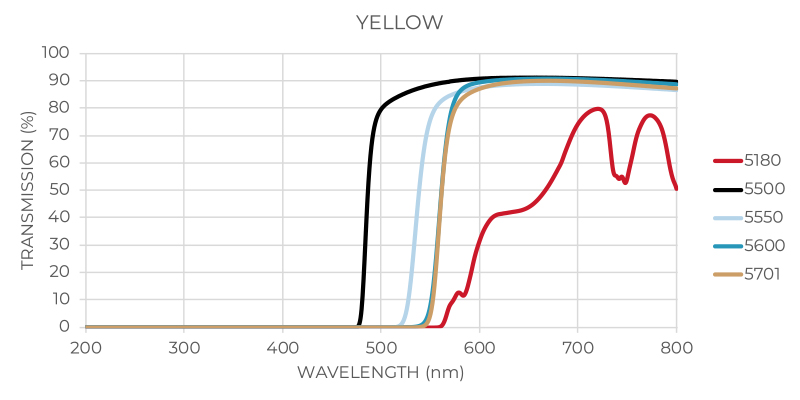

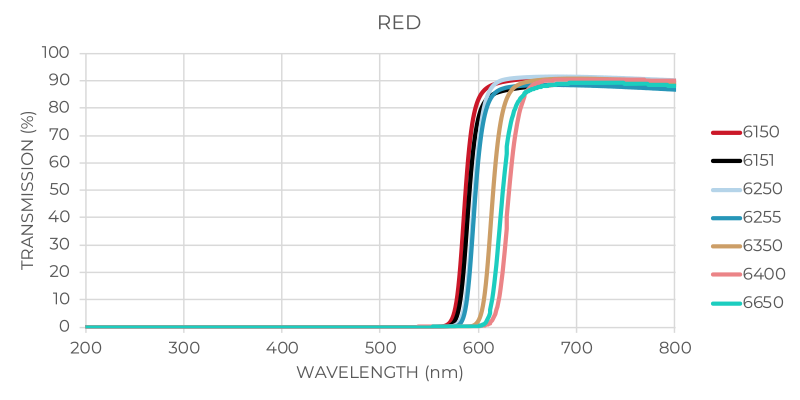

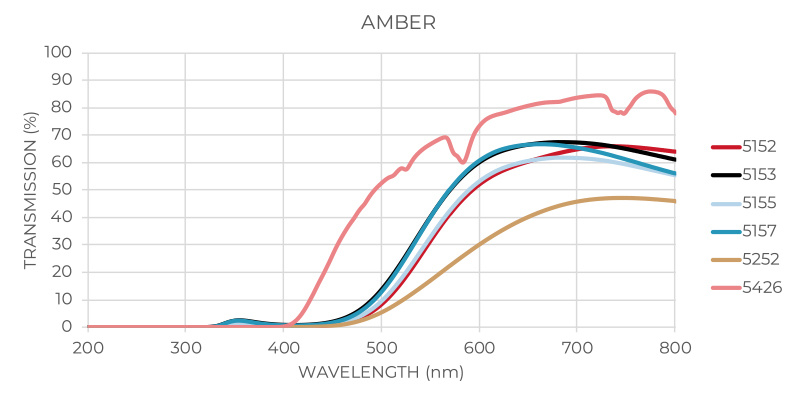

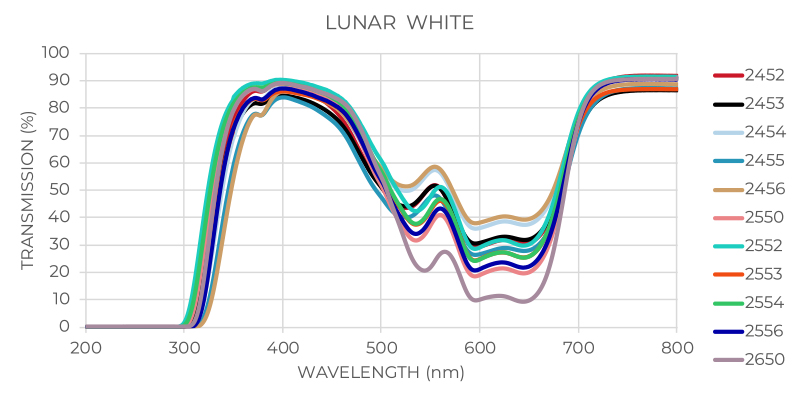

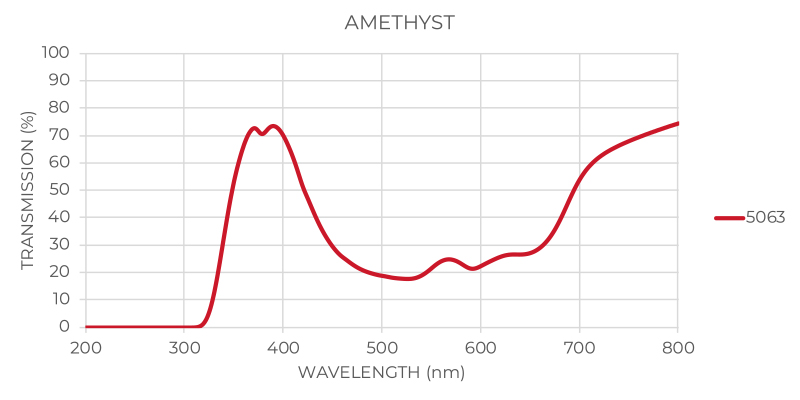

Kopp has been at the forefront of industry innovation for nearly a century. At the turn of the 20th century, with the onset of the railroad, there was a need for improved safety. We responded with the invention of "Selenium Red" glass and manufacture of these red glasses into lenses which quickly became the standard for railroad signal lighting. Since then, our ability to adapt and respond to changing technologies and deep understanding of industry requirements has enabled the expansion of our Colored Glass offerings. These glasses are engineered to withstand the punishing environments of mission-critical applications by offering superior durability, resistance to abrasion, chemical corrosion and thermal shock. They are compatible with a variety of light sources, including white and colored LEDs, plasma, HID, and incandescent.

Not only do our glasses meet our own and customer-specific performance specifications, but our glass formulations are also designed to meet industry and regulatory standards, including:

- Federal Aviation Administration (FAA)

- Military Specifications (MIL)

- International Civil Aviation Organization (ICAO)

- American Railway Engineering and Maintenance-of-Way Association (AREMA)

- SAE International (SAE)

- Institute for Traffic Engineers (ITE)

- Underwriters Laboratories (UL)

- Atmosphere Explosives (ATEX)